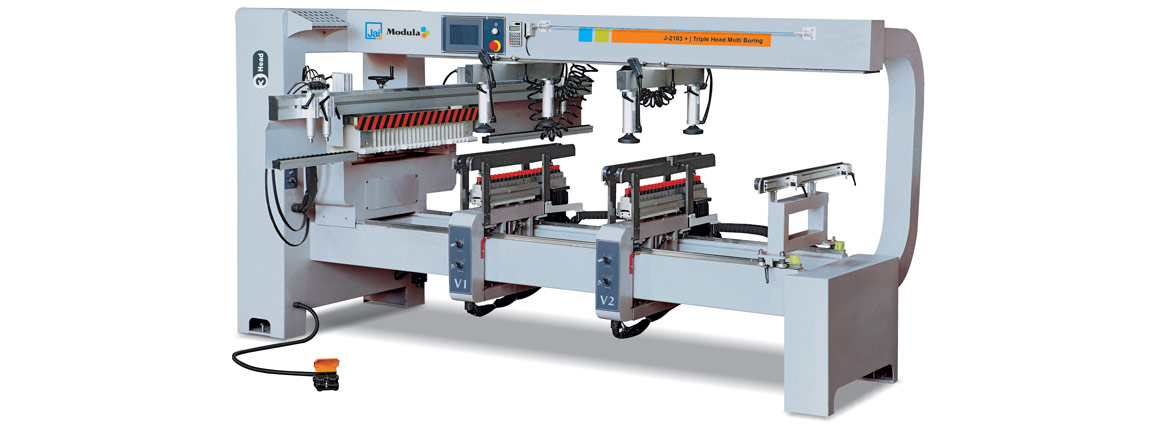

The two vertical heads can slide away one by one on rolling guides from each other.

The aluminum fence has four reference stops that slide on support rollers for smooth positioning. This makes it easy to feed long work pieces.

Quick adjustment & easy setting of horizontal boring head unit. Boring depth can be also easily adjustable. Unit has pneumatically operated solid clamp for proper clamping of work piece at front end during boring process.

User friendly smart touch PLC control panel for Quick, precise & easy setting - up.

Triple head Multi boring

Offering multiple application, flexibility & high-productivity for knock-down modular furniture industry

Salient Features : Semi-Automatic Boring machine equipped with 1 horizontal & 2 rotating vertical boring heads with 21 spindles for executing holes in a line for wardrobe side processing of knock down furniture. Quick change spindles. Strengthened frame to hold boring heads. Adequate and effective pneumatic heads. Easy and quick setting to regulate drilling depth. Elegantly designed, electro pneumatic control panel. Auxiliary support frame gives better solution for long panels with flip over brackets. Foot switch for convenient operation of the machine.

Salient Features : Semi-Automatic Boring machine equipped with 1 horizontal & 2 rotating vertical boring heads with 21 spindles for executing holes in a line for wardrobe side processing of knock down furniture. Quick change spindles. Strengthened frame to hold boring heads. Adequate and effective pneumatic heads. Easy and quick setting to regulate drilling depth. Elegantly designed, electro pneumatic control panel. Auxiliary support frame gives better solution for long panels with flip over brackets. Foot switch for convenient operation of the machine.

| Model No |

Unit |

J-2103 + |

| Max. working thickness |

mm |

60 |

| Max. size of workpiece |

mm |

1850 x 640 |

| No. of spindle head |

no's |

Three |

| No. of spindles per head |

no's |

21 |

| Total spindles |

no's |

21 + 21 + 21 = 63 |

| Minimum center distance between 2 vertical heads |

mm |

150 |

| Maximum center distance between 2 vertical heads |

mm |

1650 |

| Shank diameter of drill |

mm |

10 |

| Drilling depth |

mm |

0 - 50 |

| Air pressure required |

kg/cm2 |

6 to 7 |

| Elect. Motor / Total Power |

no/hp |

3 x 2 = 6 |

| Machine Dimensions (L x B x H) |

mm |

3000 x 3050 x 1500 |

| Approx. net weight |

kg |

900 |