With the rise of modern homes, smart interiors, and efficient storage systems, modular furniture and modular interiors are becoming the go-to choice for urban Indian households. If you’re planning to start your own factory, this guide will help you navigate everything — from choosing the right machinery to setting up your space.

Whether you’re a carpenter, interior designer, or entrepreneur, launching a modular furniture factory in 2025 is a smart and scalable business move.

Why Modular Furniture is Booming in India

- Faster Installation: Unlike traditional carpentry, modular systems are plug-and-play.

- Factory-Made Precision: Standardized fittings, clean edges, and smooth finishes.

- Growing Urban Demand: Cities like Bangalore, Mumbai, Pune, and Hyderabad are seeing a sharp rise in demand.

- Interior Designers Scaling Up: Many studios are moving from designing to manufacturing in-house.

Step-by-Step Guide to Starting Your Factory

1. Choose Your Product Focus

Will you manufacture:

- Modular Kitchens?

- Wardrobes & TV units?

- Office & commercial interiors?

Start focused, then expand.

2. Pick the Right Factory Space

- Ideal size: 2,000 to 5,000 sq. ft. to start

- Good ventilation and dust extraction space

- Located near logistics hubs or developing industrial areas

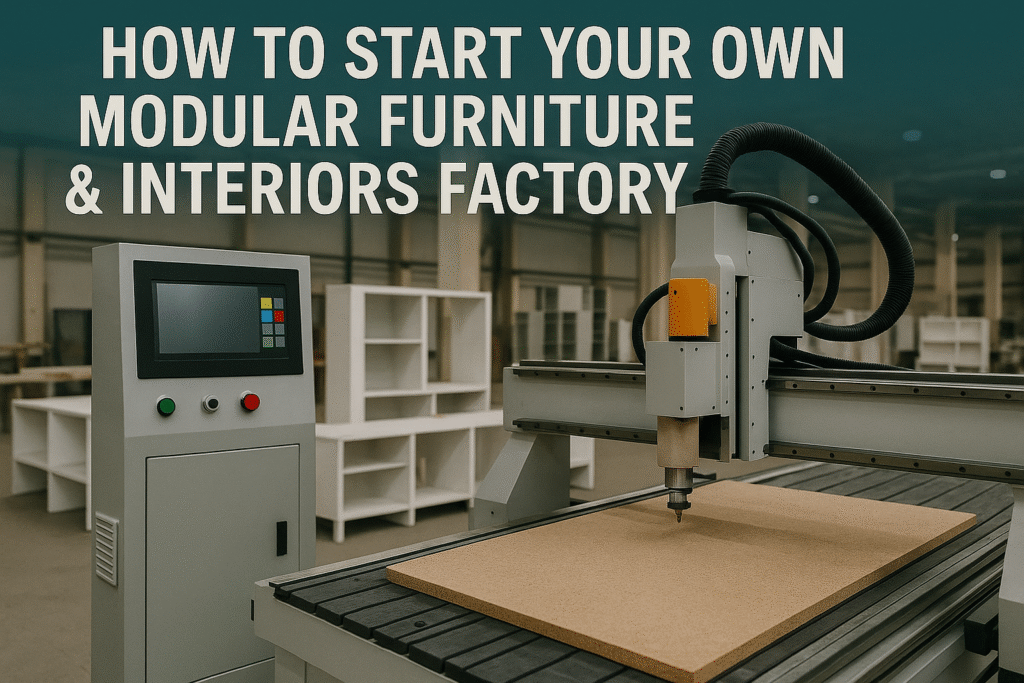

3. Select Essential Machinery

These are the must-have machines for a modular setup:

- CNC Nesting Machine

Automates cutting and drilling of all modular parts in one step. - Edge Banding Machine

Seals the edges of modular panels with clean finishes. - Panel Saw / Beam Saw

For fast, precise cutting of plywood, MDF, or particle board. - Multi-Boring Machine

Speeds up dowel and hinge hole drilling with consistency. - CNC Router (Optional)

Ideal for making grooves, profiles, and cut-outs.

Tip: Choose automatic or semi-automatic machines based on your team’s skill level and production volume.

4. Plan Workflow & Layout Smartly

- Raw panel → Cutting → Edge Banding → Drilling → Assembly

- Minimize material handling to reduce labor fatigue and increase speed

5. Train Your Staff

- CNC machines require trained operators

- Pilot Machinery offers training during and after installation

6. Market Your Brand

- Create catalogs or 3D visualizations for designers and end users

- Build partnerships with interior designers and real estate developers

Why Partner with Pilot Machinery?

Offer automation options to scale up smartly

We help design your factory layout

Recommend the right machines for your budget and scale

Provide hands-on training and service support