Solid Wood Working

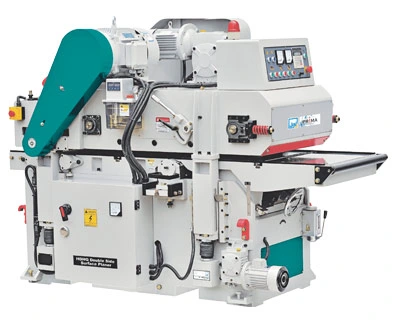

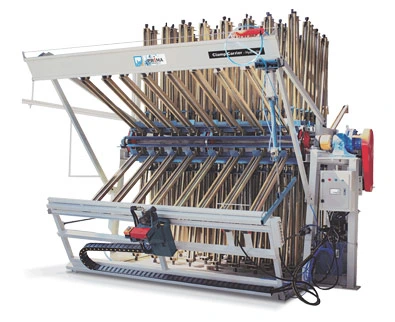

Solid Wood Working Machines are essential for precise cutting, planning, moulding, shaping, and finishing of solid wood materials. Built for reliability, accuracy, and long operational life, these machines are widely used across furniture manufacturing, carpentry units, and woodworking workshops. Each machine is designed to deliver superior performance for a variety of woodworking tasks, ensuring high productivity and excellent finish quality.

Solid Wood Working Machinery

Special Features

Heavy-Duty Frame Construction

The machines are built with robust and durable frames to withstand high workloads and ensure long-term operational stability in solid wood processing.

High-Precision Machining Components

Fitted with precision-ground tables and accurately machined components for achieving superior finish quality and dimensional accuracy.

Easy Operation and Adjustment

Designed with user-friendly mechanisms that allow for smooth adjustments of cutting depth, angles, and feed rates for various woodworking tasks.

Smooth Manual and Motorized Feed Options

Operators can choose between manual or motorized feed, ensuring flexibility for different project sizes and levels of precision needed.

Designed for Continuous Production

Built for non-stop, high-volume operation, these machines are ideal for professional workshops and industrial woodworking environments.

User-Friendly Control Systems

Equipped with ergonomic handles, levers, and switches, making machine operations intuitive, safe, and highly efficient even during extended usage.

Dust Extraction Compatibility

All machines include built-in dust extraction ports, keeping the workspace clean and improving visibility, safety, and overall working conditions.

Wide Application Versatility

Capable of handling a variety of woodworking tasks such as flattening, thicknessing, cutting, moulding, and mortising with excellent finish results.

Frequently Asked Questions

A Surface Planer is mainly used to flatten one face of a wooden board and prepare it for further sizing and shaping operations.

A Surface Planer flattens one side of the board, while a Thickness Planer ensures both sides are parallel and reduces the board to a uniform thickness.

Yes, a Combined Planer is designed to perform both operations, making it space-efficient and versatile for workshops.

Circular Saws provide fast, straight, and accurate cuts, making them ideal for sizing boards and preparing wood pieces for joinery.

Chain Mortisers use a chain mechanism (similar to a chainsaw) to carve deep mortises efficiently, particularly useful in making strong wood joints.