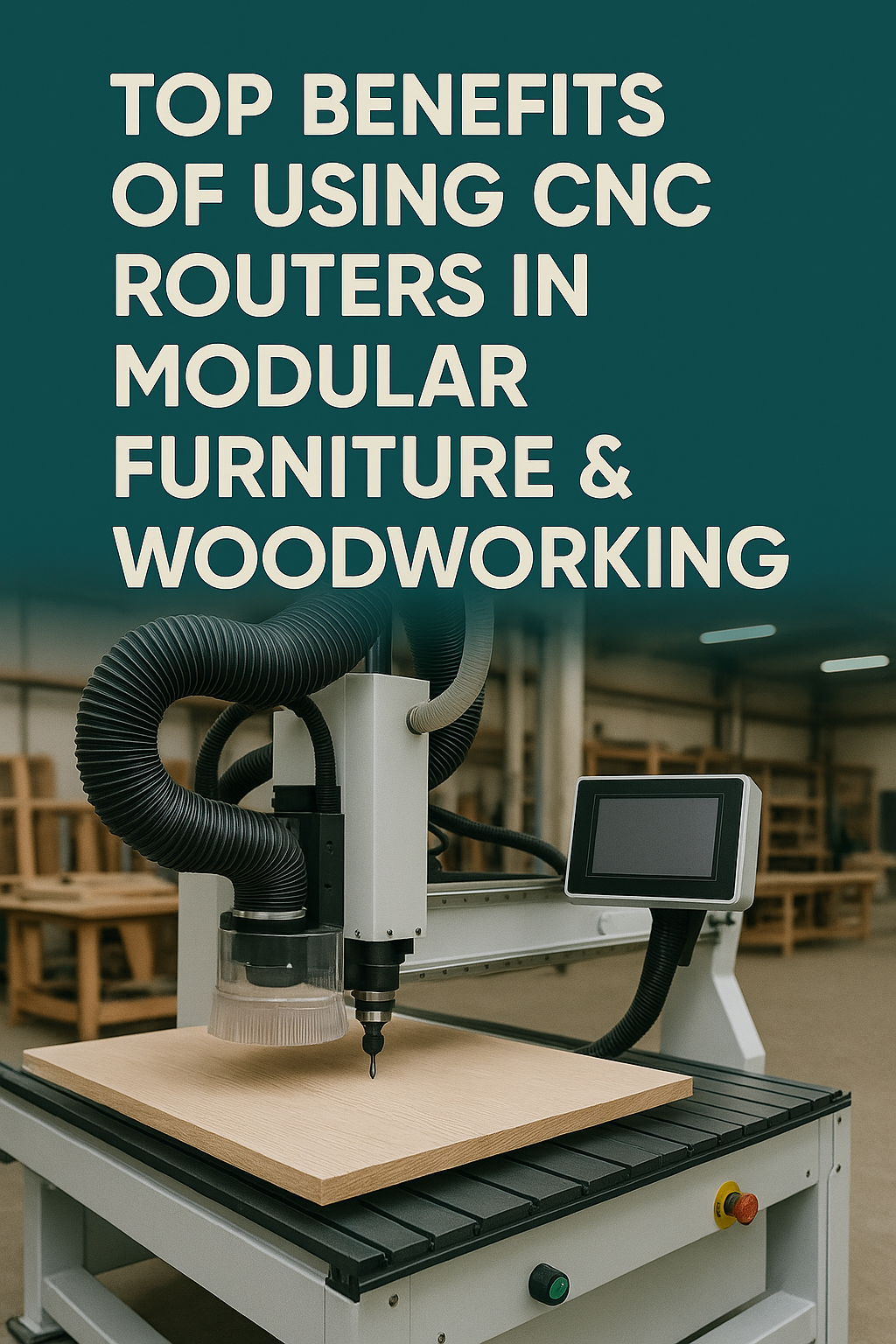

In today’s competitive manufacturing world, CNC routers are no longer a luxury — they’re a necessity. Whether you’re making modular kitchens, wardrobes, custom panels, or decorative interiors, a CNC router gives you the speed, accuracy, and versatility that traditional methods simply can’t match.

At Pilot Machinery, we offer a full range of CNC routers designed for small workshops, mid-size factories, and large-scale interior production units. Plus, we also provide options with Italian air-cooled spindles for those who want maximum performance and longevity.

Top Benefits of Using CNC Routers

1. Unmatched Cutting Precision

With CNC routers, you get flawless cuts down to fractions of a millimeter — essential for high-quality modular production.

2. Boost in Productivity

Reduce production time dramatically. A single CNC router can replace the work of multiple manual laborers.

3. Complex Designs Made Easy

From curved panels to decorative grooving and cut-outs, CNC routers let you create detailed shapes effortlessly.

4. Consistent Quality

Whether it’s the first panel or the hundredth, CNC routers deliver consistent output every time — a must for branded furniture lines.

5. Software Integration

Most CNC routers work with design software like AutoCAD or Cabinet Vision, making it easier to go from design to production.

6. Reduced Material Waste

With nesting software, you can optimize panel layouts to minimize leftover scrap.

Our Full Range of CNC Routers

At Pilot Machinery, we offer CNC routers for every need and budget:

| Model | Features | Best For |

| CNC Router – Entry Level | 3×4 ft bed, air-cooled spindle, vacuum table | Startups, custom signage, basic furniture |

| CNC Router – Standard | 4×8 ft bed, servo motors, vacuum hold, DSP control | Modular panel cutting, doors, MDF jali work |

| CNC Router – Heavy Duty | Reinforced bed, tool changer option, high RPM | Large-scale production, export-quality jobs |

| CNC Nesting Router | Auto loading/unloading, nesting software, ATC | Modular kitchens, wardrobes, volume-based production |

Optional Add-on:

We also offer machines with Italian air-cooled spindles (HSD or Colombo) — known for:

- Longer spindle life

- Lower noise and heat

- Better finish on MDF, plywood, acrylic, etc.

- Ideal for 8–12+ hour shift operations

Who Should Use CNC Routers?

- Modular furniture manufacturers

- Interior designers running their own production

- Woodworkers scaling up from manual tools

- Signage and panel decor businesses

Why Choose Pilot Machinery CNC Routers?

- Tailored models based on your budget and factory size

- Italian spindle upgrades available

- Full service, installation, and operator training

- Spare parts and maintenance support across India

Ready to Upgrade Your Factory with CNC Power?

Contact Pilot Machinery today to explore the right CNC router for your business.

Improve speed

Reduce dependency on labor

Deliver factory-quality precision every time