Edge Bander

The whole world of Panel Processing machines

Edge Bander J-4750.in

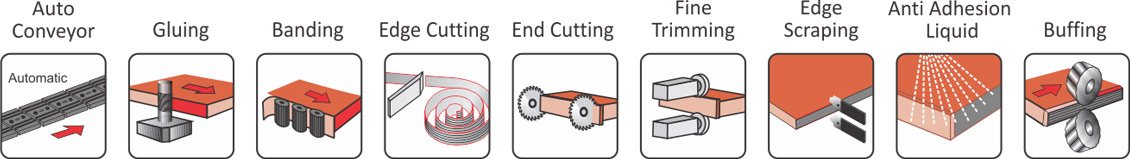

The J-4750.in boasts a robust feed chain and conveyor system with a German gearbox, providing straight movement and effective pressure for both small and large panels.

A precision machine at a lower investment and operational cost, designed to improve your production efficiency, quality, and profitability. Built to handle demanding workloads, the Edge Bander J-4750.in delivers exceptional edge banding results with minimal maintenance and superior ease of use.

Special Features

- High-speed feed system for increased productivity

- Compact high-frequency motors ensure smooth and precise edge finishing

- Automated glue temperature control for energy efficiency

- Robust German gearbox and pneumatic rollers for consistent performance

- Minimal maintenance with easy access to cost-effective spare parts

Robust feed chain & conveyor system with German gearbox gives straight movement & effective pressure on small / big panels.

Glue spreading roller provides precise & consistent glue application. Perfect adhesion to the applied edge with 2 heavy duty pressure rollers actuated by pneumatic cylinders.

Compact and powerful high frequency two independent motors guarantees best finish on edge, sliding on two prismatic guideways with recirculation ball bearings.

Compact and powerful high frequency two independent motors guarantees best finish on edge, sliding on two prismatic guideways with recirculation ball bearings.

Gives the best finishing touch to the PVC/ABS edges , leaving no trimming marks on the panel. Unit complete with rotating copiers.

Buffing : Independently adjustable buffing wheels, for cleaning & polishing of the panel edges.

Control Panel : Easy accessible user friendly control panel positioned at machine in-feed, for easy & quick operations.

Salient Features

Sturdy Construction

Heavy-duty build designed to handle tough Indian working conditions while delivering precise edge banding applications.

Robust Feed System

Equipped with a durable feed chain and conveyor system with a German gearbox for optimal panel pressure and straight movement.

High-Performance Output

With a feeding speed of 11 m/min, the machine ensures high production capacity, ideal for large-scale operations.

Pneumatic Pressure Rollers

Features two edge banding pressure rollers actuated by pneumatic cylinders, ensuring strong and consistent adhesion of edge banding material.

Precision Motors

Compact high-frequency motors glide on prismatic guideways, providing trouble-free performance and superior edge finishing.

Automatic Glue Temperature Control

The machine automatically lowers the glue temperature after periods of non-use, reducing waste and improving efficiency.

User-Friendly Control Panel

Easily accessible control panel positioned at the machine infeed for quick and simple operation.

Premium Components

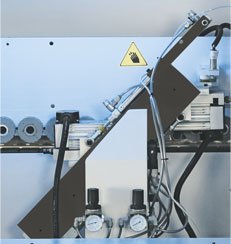

All electronic and pneumatic parts are sourced from renowned international brands to ensure reliability and longevity.

Low Maintenance

Cost-effective spare parts and best-in-class service support make this a reliable and economical choice for long-term operation.

Key Features

End Cutting

High-frequency independent motors slide on prismatic guideways with ball bearings, ensuring excellent finish and precision in end cutting.

Edge Fine Trimming

Compact motors with 2R cutters ensure a perfect rounding finish for PVC and ABS materials, offering smooth edges on straight panels.

Edge Scraping & Anti-Adhesion Liquid

For a flawless finish, the edge scraper removes any imperfections, while the anti-adhesion liquid prevents glue from sticking to the panel, maintaining a clean surface.

Buffing

Adjustable buffing wheels clean and polish the panel edges, giving them a smooth, professional look.

Control Panel

The user-friendly control panel is positioned conveniently at the infeed of the machine for easy access and quick adjustments, ensuring smooth operations.

Model No | Unit | J-4750.in |

Work piece thickness range | mm | 10 - 50 |

Minimum work piece width | mm | 120 |

Minimum work piece length | mm | 150 |

Edge Banding Thickness for PVC & ABS in coil form | mm | 0.4 - 3.0 |

Workpiece Feed | m/min | 11 |

End cutting motor power | no / hp | 2 x 0.5 |

Fine Trimming motor power | no / hp | 2 x 1 |

Buffing motor power | no / hp | 2 x 0.5 |

Air pressure required | kg/cm2 | 6 to 7 |

Working temperature range | °C | 180 - 200 |

Glue pot capacity | kg | 2 |

Total power | hp | 8.5 |

Machine dimension (L x B x H) | mm | 3350 x 950 x 1485 |

Approx net weight | kg | 1200 |

Why Choose us

Largest range of global manufacturers

Ensuring you a wide range of choices, for maximum success, suited to your needs.

Readily Available Spare Parts

At Pilot Machinery, we prioritize minimizing downtime and ensuring your operations run smoothly.

Expertly Trained Service Engineers

Our team of skilled service engineers is dedicated to delivering top-notch support and maintenance.

Trusted Industry Leader

Pilot Machinery has earned a reputation for reliability and exceptional quality.

Frequently Asked Questions

Yes, the J-4750.in is designed to handle both PVC and ABS edge banding materials efficiently, providing smooth and precise results.

The machine can handle edge banding materials up to 50 mm in height and 3 mm in thickness.

Yes, the machine automatically lowers the glue temperature during temporary non-use to conserve energy and reduce waste.