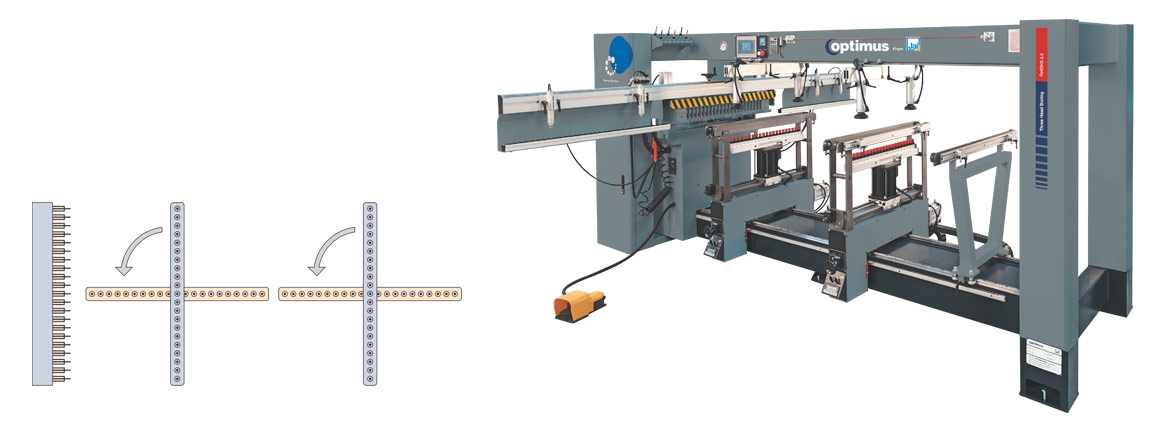

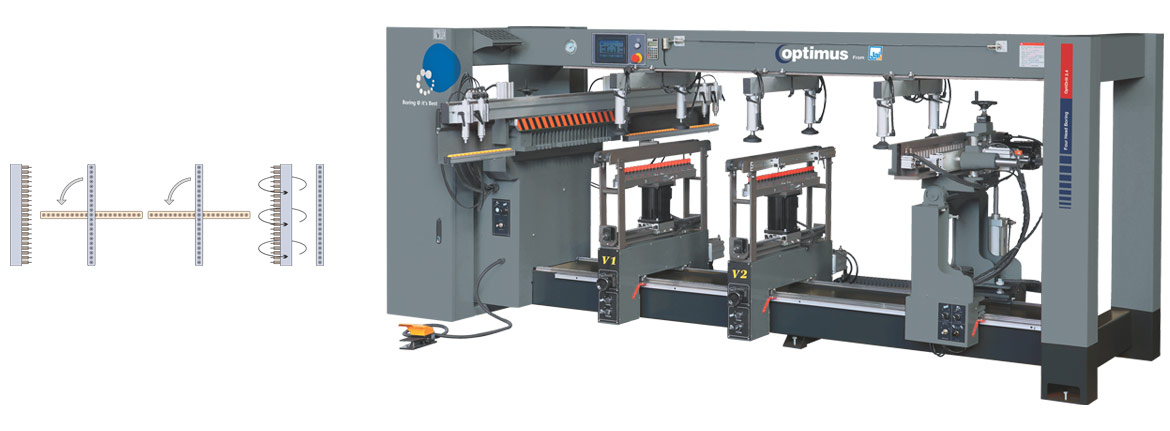

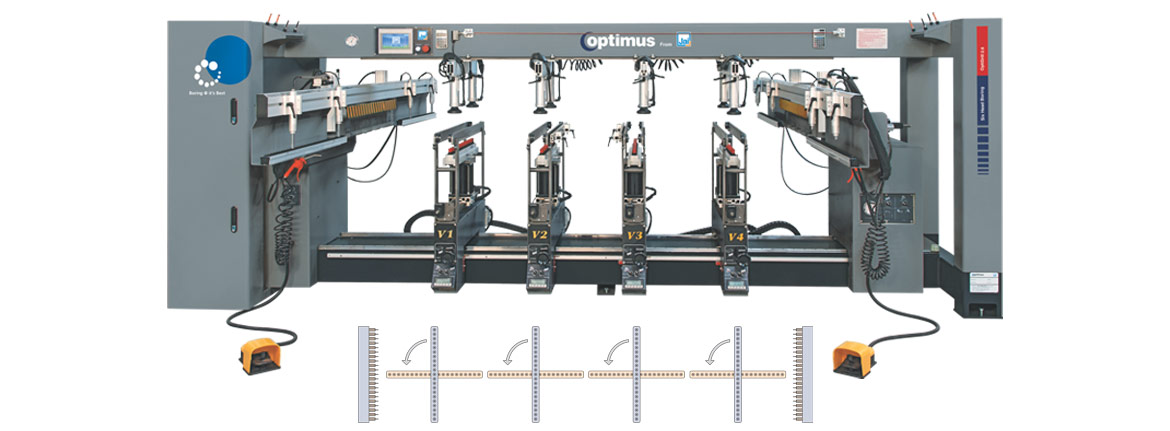

CNC Boring

Multi-Sided Boring, Routing & Grooving with Smart, Adaptive, Intelligent & Highly-Efficient CNC Processing.

Salient Features :- Processing holes needs to be as quick, easy and efficient as possible. To achieve this, the OptiBore model combines the key characteristics of speed, productivity, flexibility and user comfort in a convincing complete package. The final finishing results when processing materials convince with incredibly high standards that fulfil the ever increasing demands of boring & routing complete processing. Boring & Routing processing aggregates and an optimized machine chassis guarantee absolute stability even when running at maximum speed. With the “Professional” and “Performance” processing packages, the OptiBore can be perfectly configured for company specific requirements. Advanced CNC program designed, assure feeding device and boring /routing units are working synchronously during processing, ensure efficient processing and reduce production cost. Complete stability even at maximum processing speeds due to the solid machine chassis ....Professional machine for premium requirement Industrial constantly high performance for continuous operation Sturdy design with premium components Complete engineering precision with Uncompromised productivity Premium user comfort Sturdy built heavy-duty machine to suit Indian working condition for precise boring, grooving and routing application. High performance machine with High feeding speed gives more production. Equipped with BECKHOFF control system and integrated JAI software can edit image of the work pieces and generating NC program directly for processing. Ensuring longer machine life, safe operation, reduced unscheduled downtime and more economical operation costs.

Salient Features :- Processing holes needs to be as quick, easy and efficient as possible. To achieve this, the OptiBore model combines the key characteristics of speed, productivity, flexibility and user comfort in a convincing complete package. The final finishing results when processing materials convince with incredibly high standards that fulfil the ever increasing demands of boring & routing complete processing. Boring & Routing processing aggregates and an optimized machine chassis guarantee absolute stability even when running at maximum speed. With the “Professional” and “Performance” processing packages, the OptiBore can be perfectly configured for company specific requirements. Advanced CNC program designed, assure feeding device and boring /routing units are working synchronously during processing, ensure efficient processing and reduce production cost. Complete stability even at maximum processing speeds due to the solid machine chassis ....Professional machine for premium requirement Industrial constantly high performance for continuous operation Sturdy design with premium components Complete engineering precision with Uncompromised productivity Premium user comfort Sturdy built heavy-duty machine to suit Indian working condition for precise boring, grooving and routing application. High performance machine with High feeding speed gives more production. Equipped with BECKHOFF control system and integrated JAI software can edit image of the work pieces and generating NC program directly for processing. Ensuring longer machine life, safe operation, reduced unscheduled downtime and more economical operation costs.

| Control system | 15” PC with Beckhoff Control System | |

| Work piece processing size | Panel length - max. / min. | 2500 / 200 mm |

| Panel width - max. / min. | 850 / 70 mm | |

| Panel thickness - max. / min. | 60 / 12 mm | |

| Maximum positioning speed: | X - Axis | 25 m / min |

| Y - Axis | 25 m / min | |

| Z - Axis | 15 m / min | |

| Boring & Grooving unit : | Vertical drilling spindles | 8 no |

| Horizontal drilling spindles | 4 (X-Direction) no | |

| 2 (Y-Direction) no | ||

| Tool shank diameter | 10 mm | |

| Grooving saw diameter - X (Axis) | 120Ø mm | |

| Motor power | 2.2 kw (3 hp) | |

| Routing unit spindle : | Router spindle power | 6 kw (8 hp) |

| Spindle speed | 18000 rpm | |

| Spindle collet | ER 32 | |

| Other specifications : | Dust Extraction Port | 150Ø mm |

| Compressed Air Pressure | 7 bar | |

| Total power | 12.5 kw (16.7 hp) | |

| Machine dime. (L x B x H) | 3000 x 2000 x 1900 mm | |

| Approx. net weight | 1600 kg |