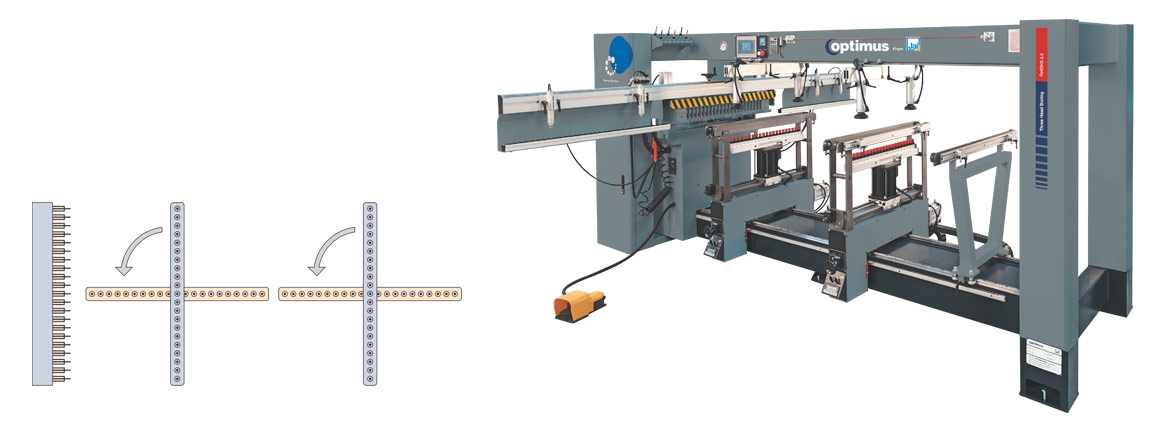

Nesting CNC Router

Salient Features :-

Nesting technology with heavy duty gantry structure ensures efficient cutting, routing, grooving & routing in one operation with panel optimization.

High performance machine with High feeding speed gives more production.

Heavy duty 2 separate air cooled 6 kw spindle & precision 9 spindle vertical boring head.

Equipped with high quality and accurate Weihong control system with servo motor & Shimpo reducer.

Stronger and large helical rack/pinion and high precision linear rails.

Save tooling and labour cost as customer requires manpower & tools only for 1 machine.

All electronic & pneumatic parts are from well-known international brands.

Ensuring longer machine life, safe operation, reduced unscheduled downtime and more economical operation costs.

Low maintenance m/c, easy available cost effective spares, best service support.

| Model | OptiRout 6.9 V |

| X - Y - Z Axis working area | 1300 x 2500 x 200 mm |

| Resolutions | 0.0025 mm |

| X - Y movement | Rack & pinion gear drive / Taiwan |

| Z movement | Heavy ball screw / TBI |

| Guide | Linear guide 30 mm - Taiwan for X & Y Axis |

| Linear guide 25 mm - Taiwan for Z Axis | |

| Spindle & boring head | 6 kw x 2, Air cooled spindle / 18000 rpm, 9V Boring head (5 + 4) |

| Boring head power | 1.5 kw |

| Controller & drive motors | WEIHONG with Servo motors & shimpo reducer |

| Working voltage | AC 380 V / 50 Hz, 3 Ø |

| Command code | G code |

| Collet type & size | ER32 (6, 8 mm) |

| Compatible software | Art Cam, Alfa Cam |

| Oil lubrication system | Standard |

| Vacuum table & pump | Standard with 7.5 kw air type pump |

| Machine dimension (L x B x H) | 4200 x 3400 x 2450 mm |

| Approx. net weight | 2500 kg |