Four Side Moulder Machine

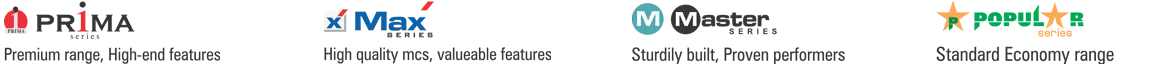

Prima series

USPs of Thickness Planer

High-Speed Performance

The top and bottom spindles reach 5000 RPM while left and right spindles hit 6000 RPM to cut things much better than ever before

Wider compatibility of workpiece

It can handle workpieces of wide dimensions, with a working width of 40–225 mm and thickness of 6–150 mm.

Durable Dust Collection System

It has a 100 mm dust collection port that helps manage debris effectively to ensure a clean workspace.

Improved Feeding Efficiency

Equipped with three gearboxes and 0.5 HP motors to ensure smooth and consistent feeding at a speed of 12 feet per minute.

Frequently Asked Questions

It is perfect for high-volume production jobs like making door frames, window frames, and wooden floors, and provides accurate contouring, width adjustment, and thickness setting all in one pass.

The machine is equipped with an anti-kickback mechanism to protect the operator during usage.