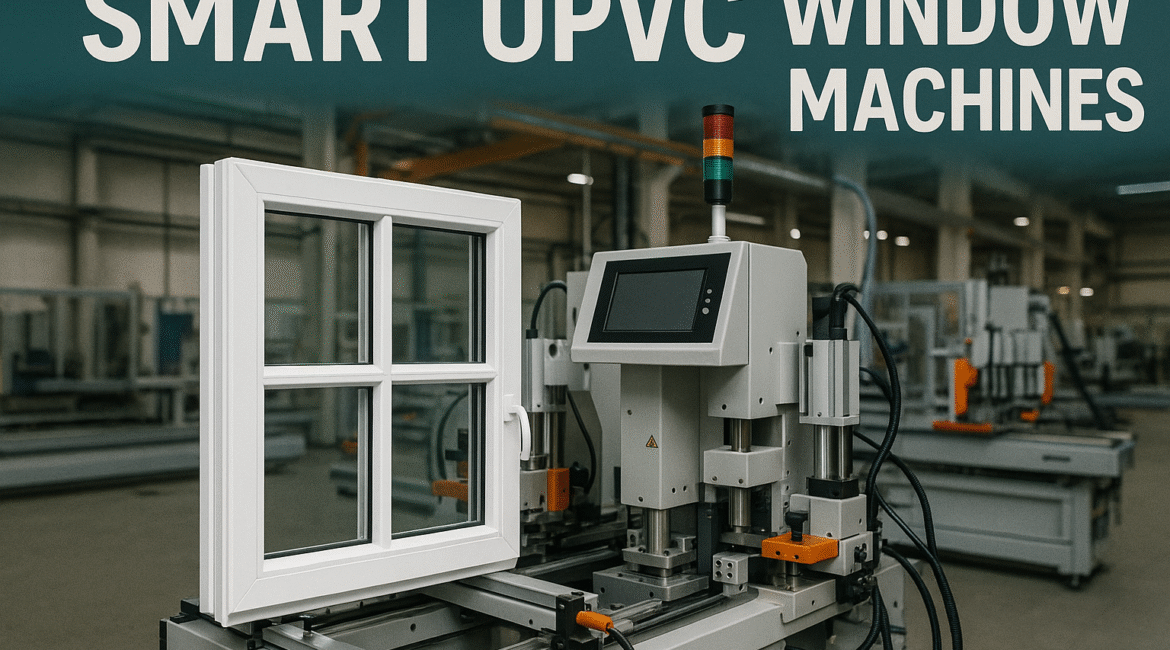

Powering the Future of Sustainable Construction

As the construction industry in India embraces modern, eco-friendly building practices, UPVC windows have emerged as the preferred choice for energy efficiency, durability, and aesthetics. With rising demand from real estate developers, architects, and homeowners, manufacturers are turning to smart UPVC window making machines to meet these expectations with speed and precision.

At Pilot Machinery, we stand at the forefront of this transformation—offering cutting-edge UPVC machinery that delivers performance, efficiency, and quality at scale.

Why UPVC Windows Are in High Demand

UPVC (Unplasticized Polyvinyl Chloride) is celebrated for its long life, resistance to weathering, and superior insulation properties. As green building certifications like IGBC and GRIHA gain traction in India, UPVC windows are becoming a go-to choice for builders who want to reduce energy bills and meet environmental standards.

How Smart UPVC Machinery Is Transforming Fabrication in 2025

1. CNC Automation for Precision Manufacturing

Modern UPVC machinery is integrated with CNC (Computer Numerical Control) technology, allowing precise cutting, welding, and milling of profiles. CNC ensures consistent quality across batches, reduces waste, and boosts output.

Example: Our Pilot CNC Double Head Cutting Machine achieves clean, accurate cuts with automatic angle adjustment—perfect for large-scale production.

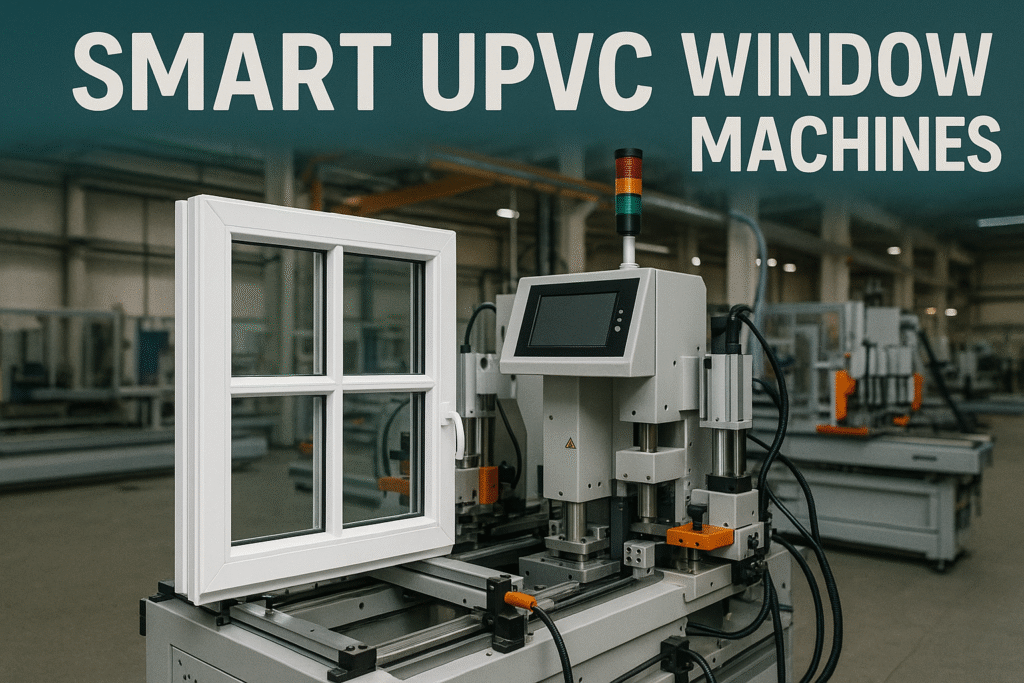

2. Touchscreen Controls & IoT Connectivity

UPVC machines now feature smart interfaces, including touchscreen panels for easy setup and adjustment. With IoT-enabled monitoring, fabricators can track machine health, production counts, and service alerts remotely—minimizing downtime and maximizing productivity.

3. Compact & Modular Designs for Urban Workshops

Urban builders and small-scale fabricators prefer space-efficient UPVC machines that offer full functionality in limited space. At Pilot Machinery, our compact fabrication units are engineered for easy installation and operation—even in tight city workshops.

4. Green Building Compliance Through Tight Tolerances

Precision machining ensures windows are manufactured with minimal gaps and perfect sealing, enhancing insulation and meeting green compliance standards. With tighter quality control, builders reduce site installation errors and improve thermal performance.

5. AI-Ready Technology for Future Upgrades

Smart UPVC machines are now designed with AI compatibility, allowing for predictive maintenance, automatic calibration, and adaptive learning—ensuring long-term efficiency and adaptability as industry needs evolve.

Why Choose Pilot Machinery for UPVC Fabrication Equipment

At Pilot Machinery, we combine innovation, reliability, and service excellence. Our UPVC window making machines are:

- Built with high-grade components for long life and durability.

- Designed for ease of use, even by new operators.

- Backed by expert support—from setup to training and maintenance.

Whether you are upgrading your fabrication line or launching a new workshop, we provide tailor-made solutions to help you grow efficiently and competitively.

Conclusion: The Future of UPVC Fabrication Is Smart, Scalable & Sustainable

With India’s real estate and construction sectors rapidly evolving, the demand for automated, smart UPVC window making machines is only set to rise. At Pilot Machinery, we’re proud to be leading this shift—empowering fabricators with the tools they need to build greener, faster, and better.

Contact us today to explore our full range of UPVC machinery and take your business to the next level.