Beam Saw – OptiCut Series

Wood is in Our Blood , Wood is Our World

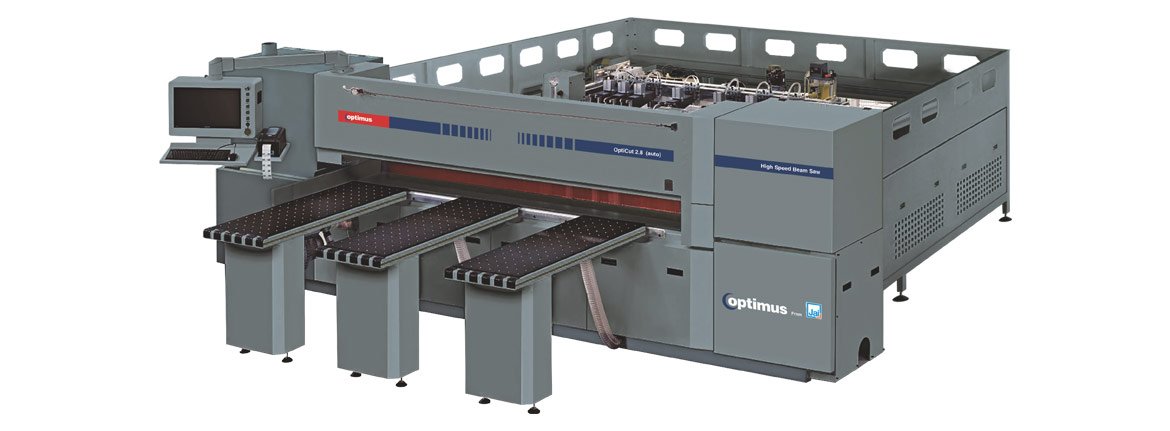

Beam Saw OptiCut 2.8 (auto)

The J-280.in Beam Saw is designed for high-speed and precise panel cutting. With a maximum cutting thickness of 60 mm, this semi-automatic machine features an infeed air floating table for easy material handling. Its advanced saw carriage, pneumatic clamping beam, and variable feed speed motor make it an ideal solution for panel processing applications.

- Model No.

- J-280.in

Features

- Robust and Stable Build:

- Balanced structure designed to withstand industrial operations, ensuring stability and precision during use.

- Cutting-Edge Technology:

- Smart Touch HD Screen with cutting-optimized software enables accurate operations, increased productivity, and reduced material wastage.

- Advanced Saw Carriage:

- Adjustable saw carriage speed (0–100 m/min) ensures flexibility for various cutting requirements.

- Integrated side aligner enhances alignment, even for thin or flexible panels, reducing cycle time.

- Air Floating Steel Ball Table:

- Prevents scratches on panels, ensuring smooth and damage-free board movement during cutting.

- High Cutting Capacity:

- Capable of handling panels up to 100 mm thickness, making it suitable for a variety of panel types.

- Reliable Components:

- All electronic and pneumatic parts sourced from renowned international brands for enhanced durability and efficiency.

- User-Friendly Design:

- Simple, intuitive controls for easy operation, even by first-time users.

- Safe and ergonomic design ensures operator comfort and minimal risk.

- Energy-Efficient Operation:

- Low maintenance requirements and cost-effective spare parts reduce operational downtime and costs.

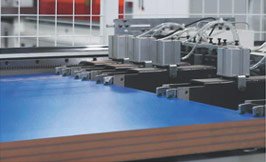

Heavy duty pneumatic suspension grippers, avoiding scratch board surface. It can gripe the panel perfectly, highly reduce labor intensity, and greatly improve production efficiency.

Air floating table to avoid scratches on board and assuring smooth board movement, suitable for heavy and big panels.

Side aligner, integrated with the saw carriage, can perfectly align given thin or flexible panel, reducing cycle cutting time.

Automatic lubrication system circulates lubrication to the required parts of the machine, ensures efficient operation and increase life of parts.

Side Aligning Motor

High precision automatic feeding servo drive system with worm gear reducer.

HD 19″ Touch screen control panel with Optimization software, provide safe, speedy cutting and reduce wastage of material.

Label Printer

OptiCut High Speed Beam Saw - Process analytical

Optimization Cutting Plan : Integration with cutting list, minimum wastage automatic optimization cutting plan.

Manual Feeding : Move the board on floating table to feeding gripper for position.

Clamping and Feeding : Feeding gripper pulls the board into the specified position in the machine.

Powerful, Precise & Efficient Panel Cutting

Automatic Side Aligning : Side wheels position the board from the side tightly to ensure precise cutting.

Automatic Press Panel : Pressure beam automatic press the panel flatly.

Automatic Output : Cut according to the size set by the program and send out automatically.

Automatic Output : Cut according to the size set by the program and send out automatically.

OptiCut 2.8 & OptiCut 3.2 - Specifications

| Specification | Unit | OptiCut 2.8 | OptiCut 3.2 |

|---|---|---|---|

| Max. Cutting Length | mm | 2800 | 3200 |

| Max. Cutting Thickness | mm | 100 | 100 |

| Saw Carriage Forward Speed | m / min | 100 | 100 |

| Saw Carriage Backward Speed | m / min | 150 | 150 |

| Main Saw Blade Size | mm | 400Φ x 60Φ | 400Φ x 60Φ |

| Speed of Main Saw Blade | rpm | 4000 | 4000 |

| Main Saw Motor | hp | 21.2 | 21.2 |

| Scoring Saw Blade Size | mm | 180Φ x 30Φ | 180Φ x 30Φ |

| Speed of Scoring Saw Blade | rpm | 6500 | 6500 |

| Auto Feeding Motor (AC Servo) | hp | 1.3 | 1.3 |

| Feeding Speed | m / min | 100 | 100 |

| Saw Carriage Drive Motor | hp | 3.0 | 3.0 |

| High Pressure Blower Motor | hp | 4.0 | 4.0 |

| Working Air Pressure | Kg / cm² | 5~7 | 5~7 |

| Total Power | hp | 29.5 | 29.5 |

| Machine Dimensions (L x B x H) | mm | 6000 x 5300 x 1500 | 6500 x 6000 x 1500 |

| Approx. Net Weight | kg | 3500 | 4000 |

Standard Accessories :-

High Productivity: Capable of high-speed, continuous production, ideal for industrial-scale operations.

Low Maintenance: Efficient design reduces downtime with readily available and cost-effective spare parts.

Smooth Operations: Advanced pneumatic and electronic systems ensure minimal disruptions and smooth performance.

Safe & Reliable: Engineered with safety mechanisms for reliable and secure usage.

Why Choose us

Largest range of global manufacturers

Ensuring you a wide range of choices, for maximum success, suited to your needs.

Readily Available Spare Parts

At Pilot Machinery, we prioritize minimizing downtime and ensuring your operations run smoothly.

Expertly Trained Service Engineers

Our team of skilled service engineers is dedicated to delivering top-notch support and maintenance.

Trusted Industry Leader

Pilot Machinery has earned a reputation for reliability and exceptional quality.

Frequently Asked Questions

The OptiCut Beam Saw can cut panels with a thickness of up to 100 mm.

Yes, it is specifically designed for high-performance industrial applications, ensuring consistent accuracy and stability.

The air floating table prevents scratches on panels, ensuring smooth movement and damage-free operation.

It features a Smart Touch HD Screen with cutting-optimized software for user-friendly and precise operations.

No, the machine is designed for low maintenance with cost-effective spare parts readily available.