Curvilinear Edge Bander J-2000.in

The whole world of Panel Processing machines

Curvilinear Edge Bander J-2000.in (Semi Auto)

The Curvilinear Edge Bander J-2000.in (Semi Auto) is a versatile and high-performance edge banding machine designed for applying PVC, ABS, and veneer on both straight and curved panels. This semi-automatic model ensures precise and efficient edge banding, making it ideal for woodworking and furniture manufacturing applications.

Equipped with an advanced glue application system, pneumatic cutting, and a durable German gearbox, the J-2000.in guarantees smooth operations and strong adhesion. The hylum-coated front working table, chrome steel rollers, and digital temperature controller contribute to a seamless and professional finish.

The glue in the glue pot, glue leveler, wiper, the extrusion screw and the heating element all make a bonding system, which gives an effective & efficient banding to the work piece.

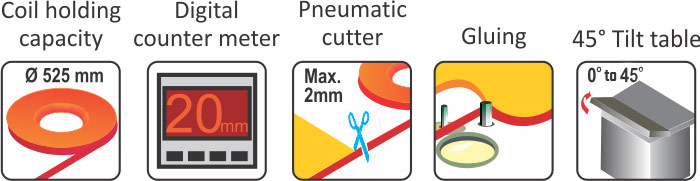

The pneumatic cutting device can be set to actuate the pneumatic cutter to cut the band for a pre-defined length using an electronic counter.

A specially designed hylum surface working table can be tilted from 0° to 45°

A user friendly electro-pneumatic control panel which monitors & controls the operation

Features

- Glue Application System: The glue roller evenly applies adhesive on both the board and tape for strong bonding.

- German Gearbox: Ensures powerful and smooth drive performance with long-life synthetic lubrication.

- User-Friendly Electro Control Panel: Monitors and controls all edge banding operations efficiently.

- Pneumatic Cutting System: Automatically actuates to cut the band precisely.

- High-Speed Operation: Consistent feed speed of 12 m/min for efficient workflow.

- Revolving Edge Coil Holder: 525mm Ø holder for smooth coil management.

- Chrome Steel & Rubber Rollers: Support and guide workpieces for accurate and stable edge banding.

- Front Table with Hylum Surface: Frictionless and heat-insulated working surface for easy maneuverability.

- Digital Temperature Controller: Ensures precise glue heating and safety by starting the motor only at the correct temperature.

- Height-Adjustable Steel Roller: Provides perfect edge pressing for a professional finish.

Key Features

- Edge coil holder plate (525mm Ø) for smooth coil management

- Glue roller system with glue leveler for precise application

- Chrome steel & rubber rollers for accurate guiding and support

- Electro-pneumatic control panel for efficient operation

Model Specifications - J-2000.in

| Specification | Value |

|---|---|

| Table Size (L x B) | 1100 x 800 mm |

| Minimum Work Piece Length | 280 mm |

| Work Piece Thickness Range | 10 - 50 mm |

| Edge Banding Thickness (PVC & ABS in Coil Form) | 0.4 - 2.0 mm |

| Min-Radius for Curved Edging | 20 mm |

| Glue Pot Capacity | 1.5 kg |

| Feed Speed | 12 m/min |

| Maximum Setting Temperature | 180°C |

| Compressed Air Requirement | 0.5 hp / 5-7 kg/cm² |

| Heating Element | 1.5 kW |

| Electric Motor | 0.37 kW (415V, 3Ø) |

| Power Supply | 415V, 3Ø |

| Total Power | 2.5 hp |

| Machine Dimension (L x B x H) | 1650 x 950 x 950 mm |

| Approx. Net Weight | 215 kg |

Standard Accessories

- Edge coil holder plate (525mm Ø) for smooth coil management

- Glue roller system with glue leveler for precise application

- Chrome steel & rubber rollers for accurate guiding and support

- Electro-pneumatic control panel for easy operation

Why Choose us

Largest range of global manufacturers

Ensuring you a wide range of choices, for maximum success, suited to your needs.

Readily Available Spare Parts

At Pilot Machinery, we prioritize minimizing downtime and ensuring your operations run smoothly.

Expertly Trained Service Engineers

Our team of skilled service engineers is dedicated to delivering top-notch support and maintenance.

Trusted Industry Leader

Pilot Machinery has earned a reputation for reliability and exceptional quality.

Frequently Asked Questions

The J-2000.in supports PVC, ABS, and veneer for both straight and curved edge banding applications.

Yes, the digital temperature controller ensures precise glue heating and prevents overheating or drying.

No, the J-2000.in has a fixed working table, but its hylum-coated surface ensures smooth movement.

The minimum workpiece length for the J-2000.in is 280mm.

The J-2000.in operates at a fixed speed of 12 m/min.