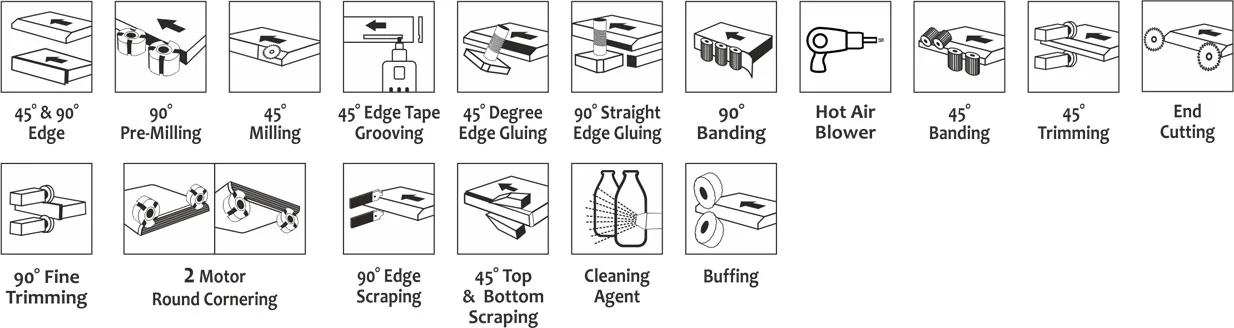

45° Edge Banding in a Single Pass – Transforms straight panels into 45° edge panels seamlessly.

High-Speed Production – 12 m/min feed speed for enhanced productivity.

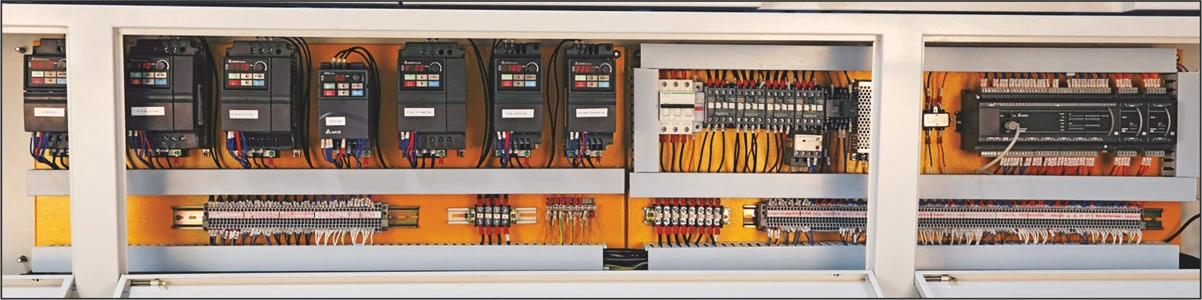

Smart Touch PLC Control – Finger-touch operation eliminates the need for manual adjustments.

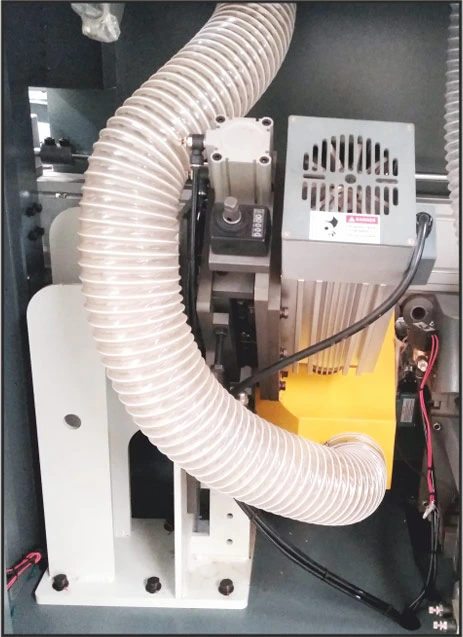

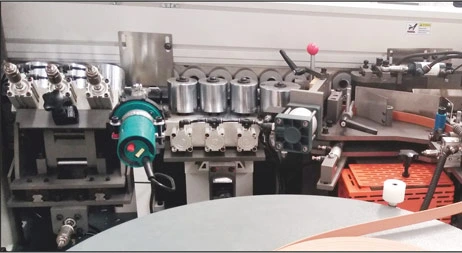

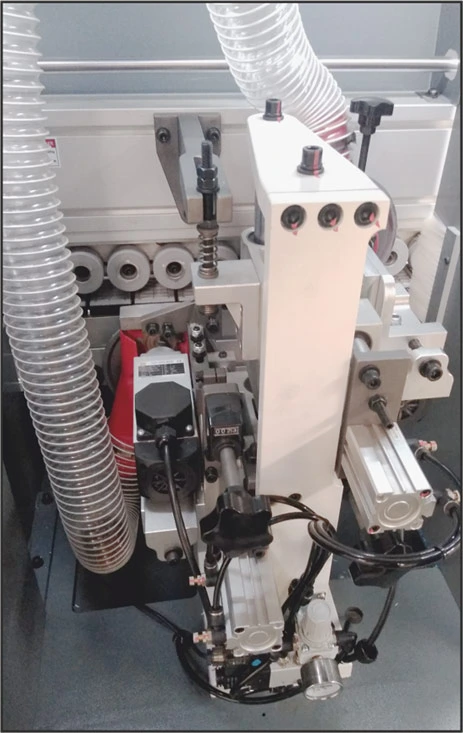

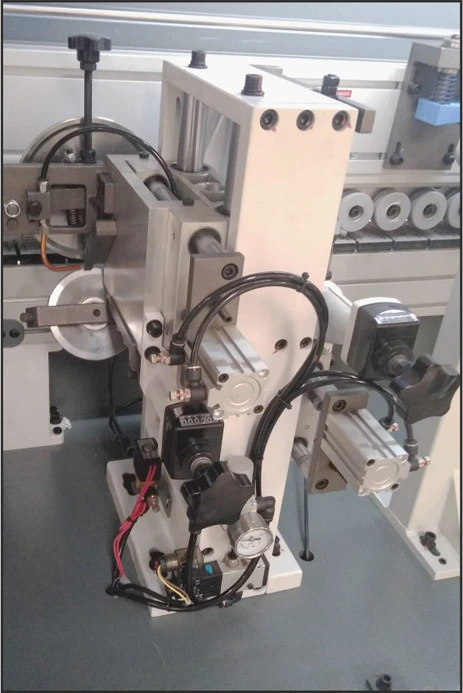

Heavy-Duty Pre-Milling Unit – Two high-frequency motors with diamond cutters ensure a smooth and precise edge before banding.

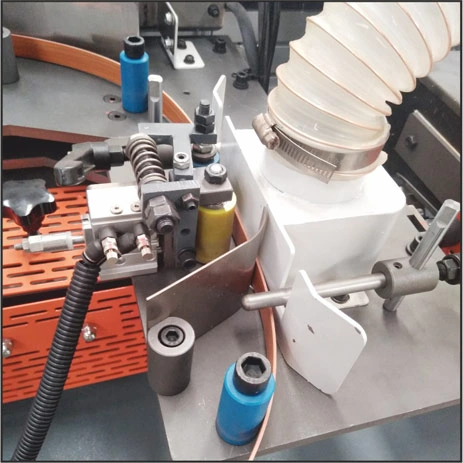

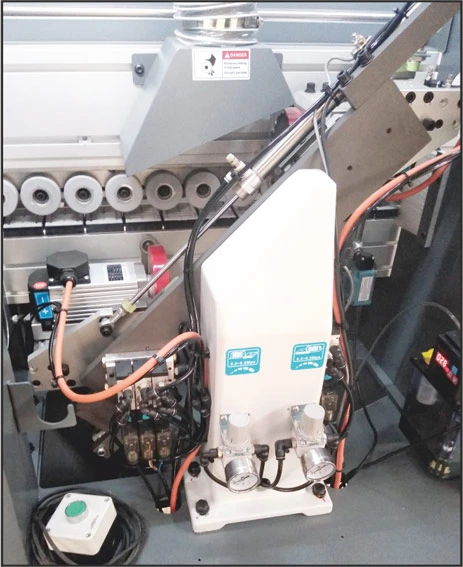

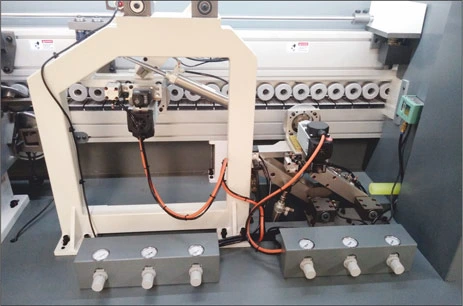

Independent Twin Glue Tanks – Ensures perfect glue application on both the degree edge and straight edge.

Automatic Lubrication System – Extends the lifespan of critical machine parts and ensures smooth operation.

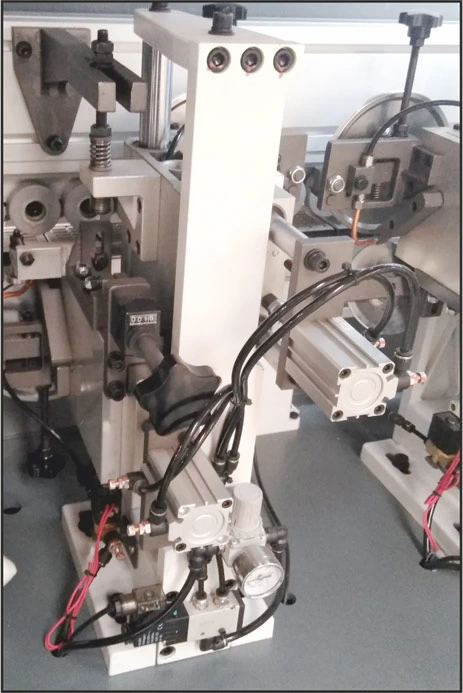

Motorized Pressure Beam – Allows easy thickness adjustments for quick operations.

Robust Feed Chain & Conveyor System – Equipped with a heavy-duty gearbox for precise pressure on panels.

Special Features

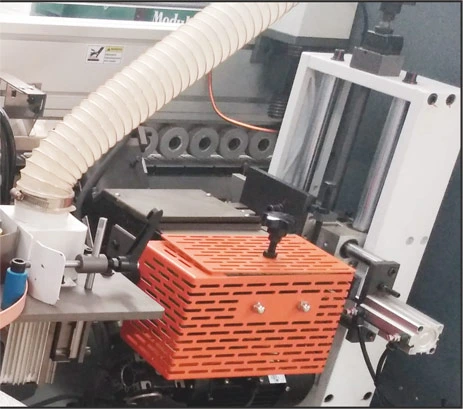

45° Edge Tape Grooving – Uses diamond groove cutters for accurate edge banding.

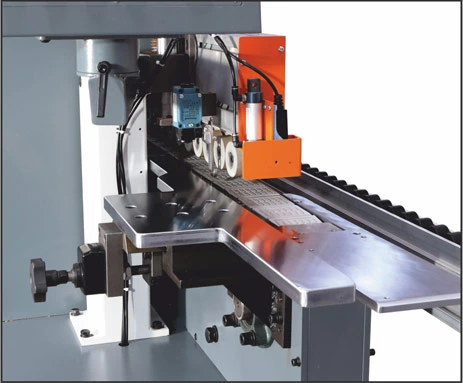

End Cutting with Pneumatic Pressure – Heavy-duty knife system cuts edge banding materials smoothly up to 25 mm height & 2 mm thickness.

45° Top Flat Scraping & Buffing – Delivers a perfect finish without trimming marks, leaving polished, professional edges.

Low-Maintenance Design – Uses cost-effective, easily available spare parts for long-term reliability.