OptiEdge 8.5

Redefining Panel Processing Technology

OptiEdge 8.5 – High-Speed Auto Edge Bander

Product Description

The OptiEdge 8.5 is a high-speed auto edge bander designed for both 45° and 90° edge banding panels, offering unmatched precision, speed, and efficiency. With a feeding speed of up to 25 m/min, independent twin glue tanks, and an advanced Smart Touch PLC control panel, this machine provides a seamless and automated edge banding process. Equipped with pre-milling, trimming, scraping, and buffing units, it ensures a perfect finish for furniture and panel processing applications. Heavy-duty construction, automatic lubrication, and international-standard electronic and pneumatic components make the OptiEdge 8.5 a high-performance, low-maintenance solution for large-scale production.

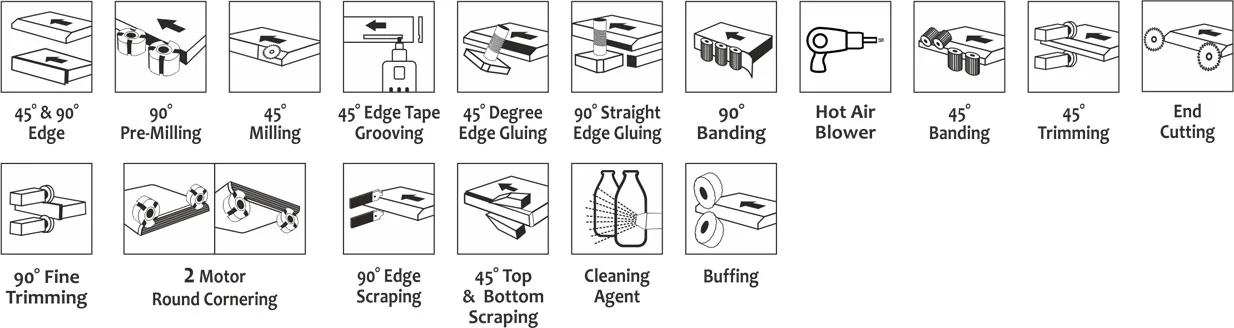

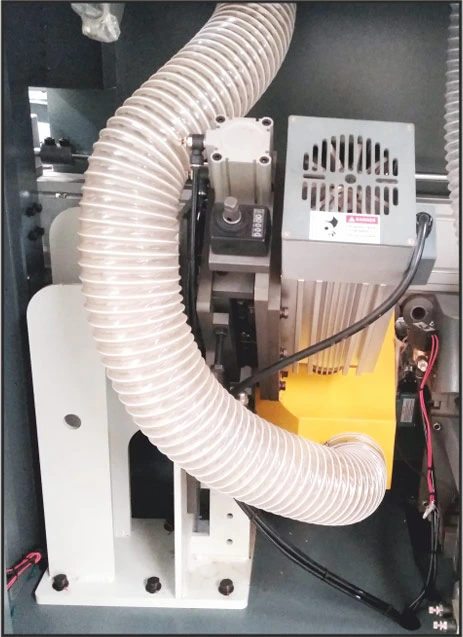

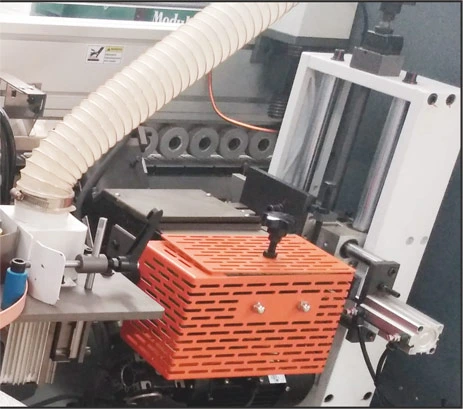

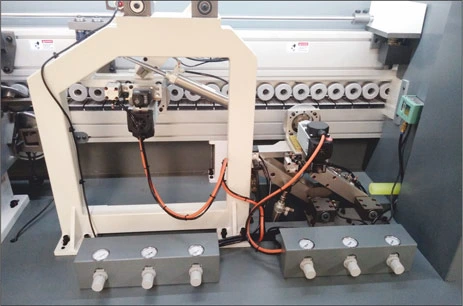

Pre – Milling : An optimal unit for panel edge pre-milling with two heavy duty high frequency motors supplied with set of diamond cutters, as standard supply with machine.

45° Milling : An optimal unit to make panel edge 45°, with 7.5 hp heavy duty high frequency motor in single pass.

45° Edge Tape Grooving : An optimal unit for edge tape grooving to make proper banding with panel with diamond groove cutter, as standard supply with machine.

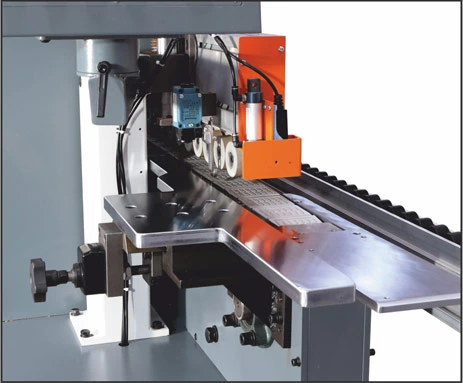

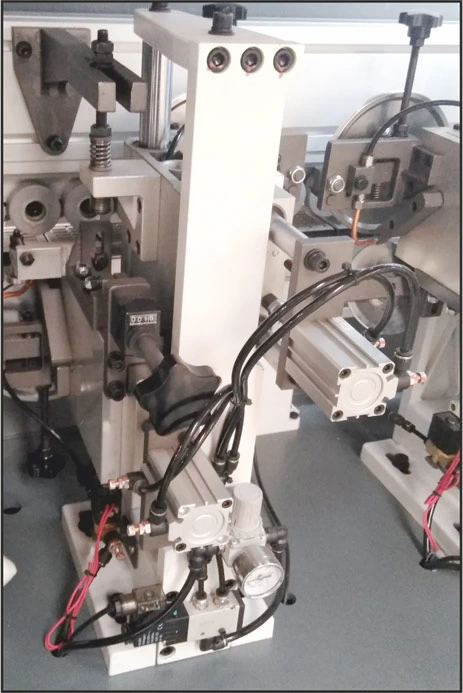

The Feed Track : Robust feed chain & conveyor system with heavy duty gearbox gives straight movement effective pressure on small / big panels.

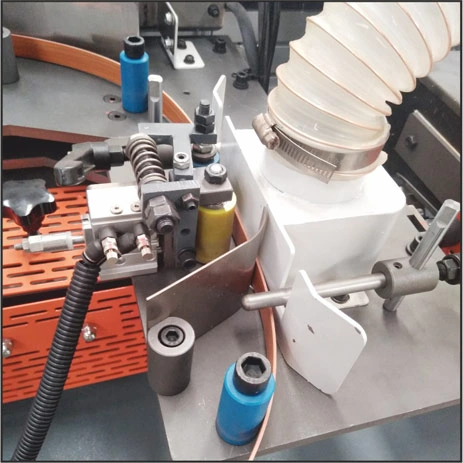

45° Gluing, Banding & Edge Cutting : Glue spreading roller provides precise & consistent glue application. Perfect adhesion to the applied edge with heavy duty pressure rollers.There are three groups of pressure rollers for proper adhesion on inclined edge. Heavy duty knife with pneumatic pressure cuts the edge banding materials smoothly up to 25 mm height & 2 mm thickness.

90° Gluing, Banding & Edge Cutting : Glue spreading roller provides precise & consistent glue application.Perfect adhesion to the applied edge with 4 heavy duty pressure rollers.Heavy duty knife with pneumatic pressure cuts the edge banding materials smoothly up to 60 mm height & 3 mm thickness.

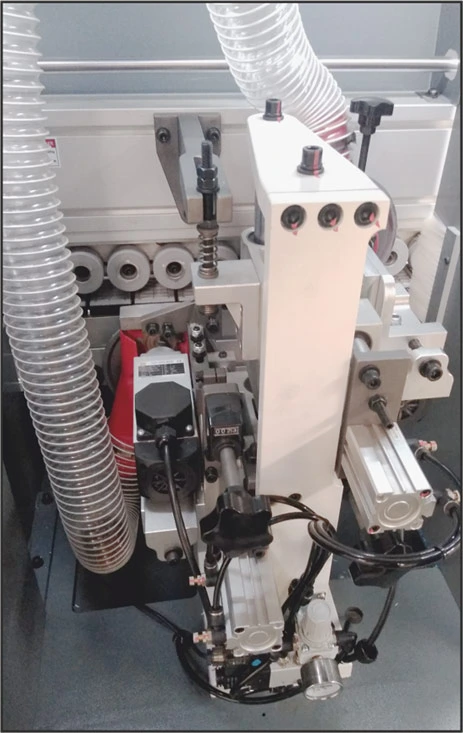

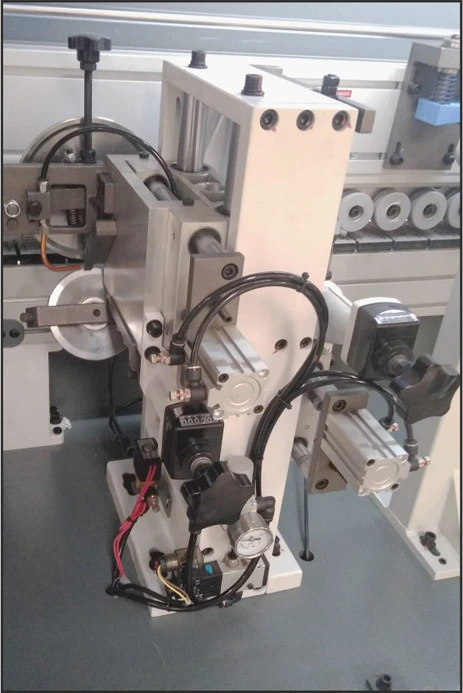

45° Trimming : Compact and powerful high frequency two motors guarantees perfect finish on edge. High level finishing thanks to the sturdy & heavy duty structure which is free of any vibration. Trimmer cutter trims the perfect finishing on straight edge of panel.

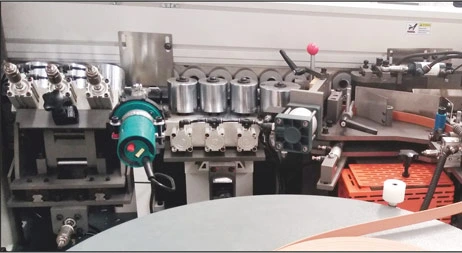

End Cutting : Compact and powerful high frequency two motors guarantees perfect finish on edge, sliding on two prismatic heavy guideways with recirculation ball bearings.

90° Fine Trimming : Compact and powerful high frequency two motors guarantees perfect finish on edge. High level finishing thanks to the sturdy & heavy duty structure which is free of any vibration. Trimmer 2R cutter trims the perfect finishing on straight edge of panel.

2 Motor Round Cornerning : Compact and powerful high frequency two motor round cornering unit guarantees perfect finish on edge, sliding on two heavy prismatic guideways with recirculation ball bearings. Trimmer 2R cutter for PVC/ABS gives perfect rounding on edges of straight, chamfered & post formed panel.

90° Edge Scraping : Gives the best finishing touch to the PVC/ABS edges, leaving no trimming marks on the panel. Unit complete with rotating copiers.

45° Flat Scrapping : Gives the best finishing touch to the PVC/ABS edges, leaving no trimming marks on the panel. Unit complete with rotating copiers.

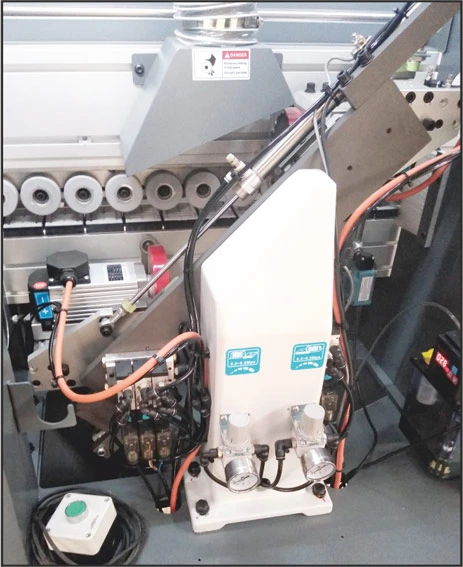

Cleaning Agent : In order to prevent glue to adhere on panel, cleaning liquid is sprayed to lower & upper edge surface of the panel. Buffing : Perfect straight & degree edge banding finishing by unit. Independently adjustable buffing wheels, for cleaning & polishing of the panel. It can be adjustable at a particular angle to maximize its effect for perfect finishing of workpiece & increase the life of buffing wheels.

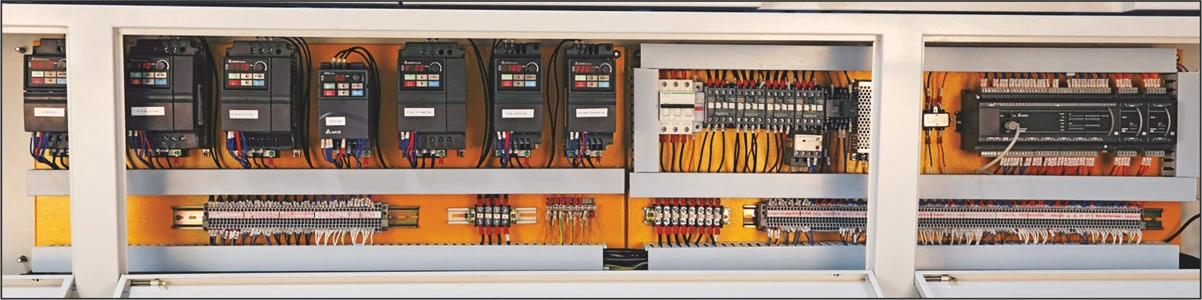

Control Panel : Easy accessible user friendly Smart Touch PLC control panel positioned at machine in-feed, for easy & quick operations.

Pressure Beam Up-down : Motorized up-down movement of pressure beam for easy thickness setting for quick operation from control panel.

Auto Lubrication : Automatic lubrication system circulates lubrication to the required parts of the machine, ensures efficient operation and increase life of parts.

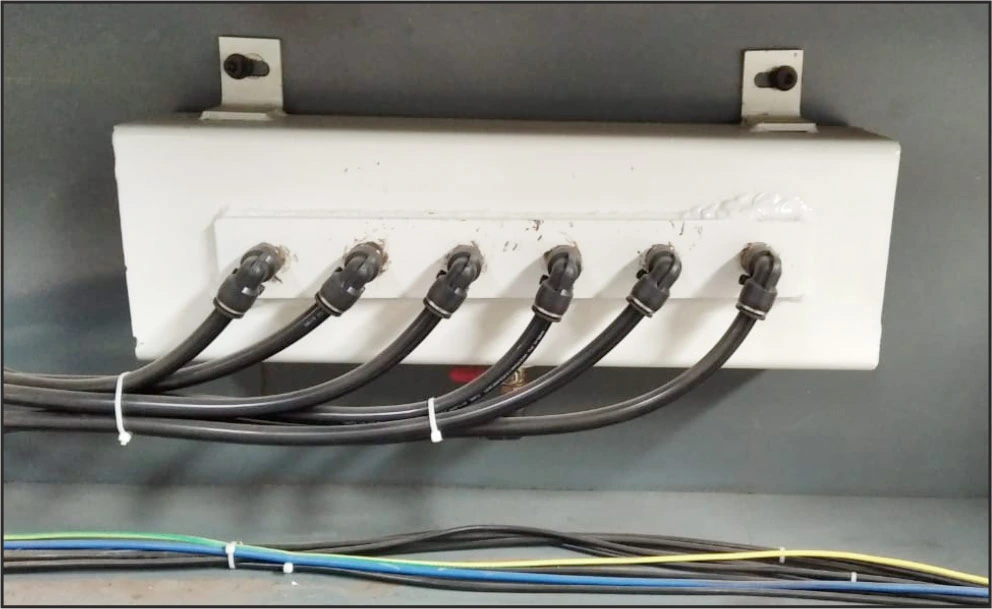

Air pressure safety tanks are provided to ensure non-dropping of air during process.

Key Features

Dual Edge Banding Capability – Supports both 45° and 90° edge banding in a single pass.

High-Speed Operation – Feeding speed up to 25 m/min, increasing production efficiency.

Diamond-Cutter Pre-Milling – Equipped with twin heavy-duty motors and diamond cutters for precise panel preparation.

Smart Touch PLC Control – One-touch adjustment eliminates manual setup for effortless operation.

Heavy-Duty Pre-Milling Unit – Two high-frequency motors with diamond cutters ensure precise and smooth edge preparation.

Independent Twin Glue Tanks – Ensures accurate and consistent glue application on both the degree and straight edges.

Automatic Lubrication System – Circulates lubrication to critical parts, ensuring longer machine life.

Safety Air Tank System – Prevents air pressure drops during operation for consistent performance.

Special Features

Robust Conveyor & Feed Chain System – Heavy-duty gearbox applies effective pressure on panels for accurate movement.

45° and 90° Trimming & Edge Cutting – Powerful high-frequency motors deliver a vibration-free, smooth finish.

Edge Scraping & Flat Scraping – Rotating copiers ensure a flawless finish without trimming marks.

Advanced Buffing System – Dual buffing wheels clean and polish panels for a refined appearance.

Low Maintenance & Cost-Effective Spares – Built with internationally recognized components for long-lasting performance.

OptiEdge 8.5 - Specifications

| Specification | Value |

|---|---|

| Work Piece Thickness Range | |

| Inclined 45° Edge | 10 - 25 mm |

| Full Straight 90° Edge | 10 - 60 mm |

| Work Piece Size - Width x Length | |

| Inclined 45° Edge | 120 - 150 mm |

| Full Straight 90° Edge | 80 - 120 mm |

| Edge Banding Thickness for PVC & ABS in Coil Form | |

| Inclined 45° Edge | 0.4 - 2.0 mm |

| Full Straight 90° Edge | 0.4 - 3.0 mm |

| Work Piece Feeding Speed | |

| Inclined 45° Edge | 15 m/min |

| Full Straight 90° Edge | 15 - 20 - 25 m/min |

| Pre-Milling Motor Power | 2 × 3 hp |

| 45° Milling Motor Power | 1 × 5 hp |

| End Cutting Motor Power | 2 × 0.5 hp |

| 90° & 45° Trimming Motor Power | 4 × 1 hp |

| Buffing Motor Power | 2 × 0.5 hp |

| Air Pressure Required | 6 to 8 kg/cm² |

| Working Temperature Range | 180 - 200 ºC |

| Glue Pot Capacity | 2.0 kg |

| Total Power | 32.5 hp |

| Machine Dimension (L x B x H) | 8200 x 1530 x 1600 mm |

| Approx. Net Weight | 2700 kg |

Standard Accessories

Diamond cutters for pre-milling and edge tape grooving

Independent twin glue tanks for precise glue application

Heavy-duty pressure rollers for superior edge adhesion

Smart Touch PLC control panel for fully automated operation

Automatic lubrication system for efficient machine performance

Rotating copiers for top flat scraping

Heavy-duty trimming motors for clean, smooth finishing

Robust conveyor and feed chain system for stable panel movement

Toolkit and user manual for maintenance and setup

Machining Examples

Why Choose us

Largest range of global manufacturers

Ensuring you a wide range of choices, for maximum success, suited to your needs.

Readily Available Spare Parts

At Pilot Machinery, we prioritize minimizing downtime and ensuring your operations run smoothly.

Expertly Trained Service Engineers

Our team of skilled service engineers is dedicated to delivering top-notch support and maintenance.

Trusted Industry Leader

Pilot Machinery has earned a reputation for reliability and exceptional quality.

Frequently Asked Questions

It is designed for both 45° and 90° edge banding, providing dual functionality in a single machine.

The high-frequency pre-milling motors with diamond cutters ensure a perfectly smooth edge before applying glue, resulting in strong adhesion.

Yes, the Smart Touch PLC control panel allows one-touch switching between 45° and 90° edge banding without manual adjustments.

Each glue tank applies adhesive separately to the 45° and 90° edges, ensuring perfect bonding for each type of panel.

The air pressure safety tank prevents air drops during processing, maintaining consistent performance throughout the cycle.

It is built with high-quality international components, features an automatic lubrication system, and uses cost-effective spare parts that are easily available.