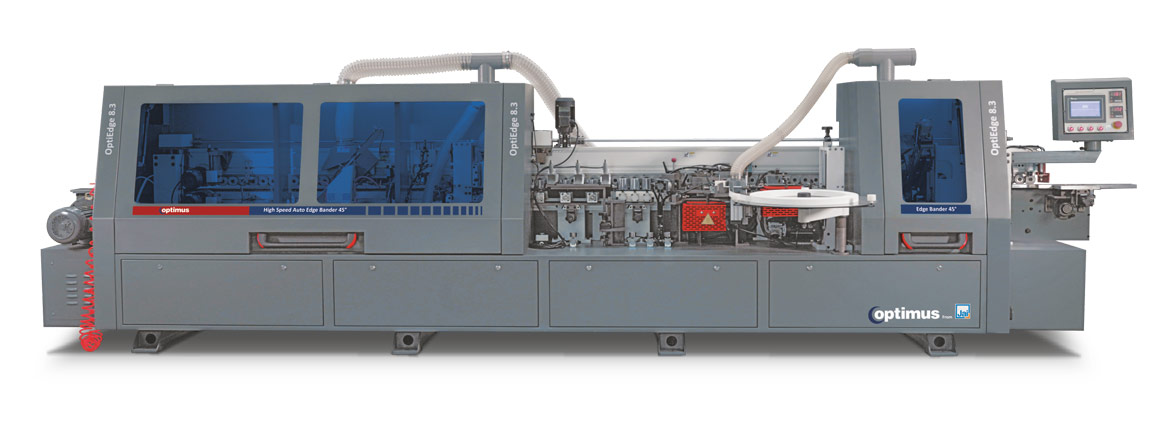

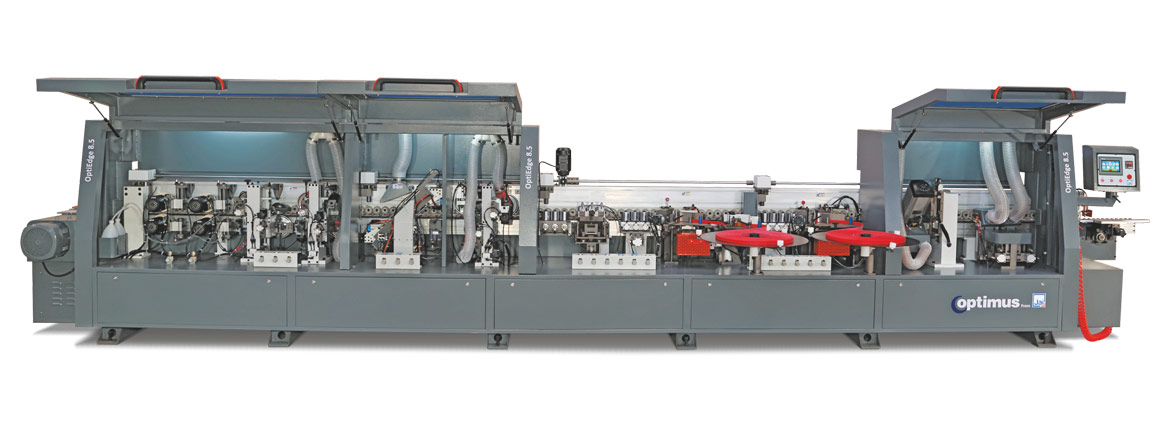

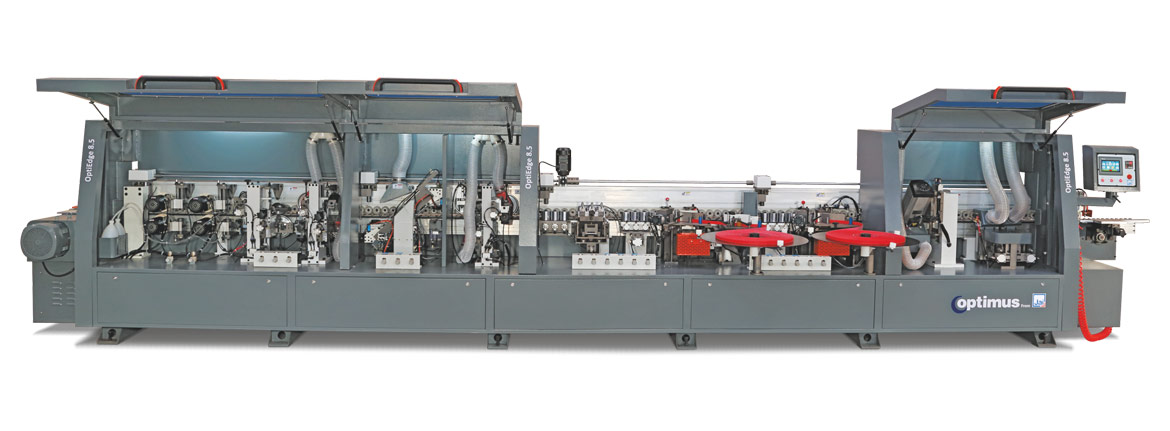

High Speed Auto Edge Banders – 45° & 90°

Edge Bander for manufacturing only 45° Edge Banding Panels

Salient Features :- 45° Panel Edge from straight panel in single pass High performance machine with High feeding speed up to 12 m/min gives more production. 45° Edge Banding function by finger touch from Smart Touch PLC control panel. No need to adjust any units / parts. An optimal unit for panel edge pre-milling with two heavy duty high frequency motors supplied with set of diamond cutters, as standard supply with machine. Motorized up-down movement of pressure beam for easy thickness setting. High frequency motors sliding on heavy prismatic guide ways for perfect finishing with trouble free performance. Independent twin glue tanks apply the glue to the degree edge and straight edge of panel . Both glue spreading roller provides precise & consistent glue application. Perfect adhesion to the applied edge due to heavy duty pressure rollers. Automatic lubrication system circulates lubrication to the required parts of the machine, ensures efficient operation and increase life of parts. Robust feed chain & conveyor system with heavy duty gearbox for effective pressure on panels. All electronic & pneumatic parts are from well-known international brands.

Salient Features :- 45° Panel Edge from straight panel in single pass High performance machine with High feeding speed up to 12 m/min gives more production. 45° Edge Banding function by finger touch from Smart Touch PLC control panel. No need to adjust any units / parts. An optimal unit for panel edge pre-milling with two heavy duty high frequency motors supplied with set of diamond cutters, as standard supply with machine. Motorized up-down movement of pressure beam for easy thickness setting. High frequency motors sliding on heavy prismatic guide ways for perfect finishing with trouble free performance. Independent twin glue tanks apply the glue to the degree edge and straight edge of panel . Both glue spreading roller provides precise & consistent glue application. Perfect adhesion to the applied edge due to heavy duty pressure rollers. Automatic lubrication system circulates lubrication to the required parts of the machine, ensures efficient operation and increase life of parts. Robust feed chain & conveyor system with heavy duty gearbox for effective pressure on panels. All electronic & pneumatic parts are from well-known international brands.

| Model | Unit |

OptiEdge 8.3 |

Only 45° |

||

| Work piece thickness range | ||

| - Inclined 45° edge | mm |

12 - 25 |

| Minimum workpiece width | mm |

120 |

| Minimum workpiece length | mm |

250 |

| Edge banding thickness for PVC & ABS in coil form | ||

| - Inclined 45° edge | mm |

0.4 - 2.0 |

| Work piece feeding speed | m / min |

12 |

| Pre-milling motor power | no / hp |

2 x 3 |

| 45° milling motor power | no/hp |

1 x 5 |

| Trimming motor power | no/hp |

2 x 1 |

| End cutting motor power | no/hp |

2 x 0.5 |

| Buffing motor power | no/hp |

2 x 0.5 |

| Air pressure required | kg/cm2 |

6 to 8 |

| Working temperature range | °C |

180 - 200 |

| Glue pot capacity | kg |

2.0 |

| Total power | hp |

30.5 |

| Machine dimension (L x B x H) | mm |

7100 x 1530 x 1600 |

| Approx. net weight | kg |

2400 |